The Parameter ofDirect Factory high speed Diamond wire mesh weaving machine:

Â

| Model | SMHN-001 |

| Wire diameter | 1.5-4mm |

| Mesh opening size | 25-120mm |

| Width of mesh | 0.5-4m |

| power | 9.25kw |

| Forming spindle speed | 275-1100 rpm (adjustable speed)Â |

| size |

6700mm*1430mm*1800mm 5100mm*1700mm*1250mm |

| Weight | 4.2T |

| Capacity | 120 Square meters per hour |

The advantage:

1.Designed for continuous working system as 24 hours.

2.Double wire input

3.Two sets mold for free

4.Long using time for mold

5.Low tolerance for mold +/-1mm

6.Wire fencing option up to 6Â meters height.(the minimum could be any size)

7.Wire fencing capacity(speed):120m2/hour-(as result of tests 100mm mesh size)

8.It works with any thickness between of wire 1.5mm and 4.0mm.

9.Between 25mm-120mm of mesh size wire fencing

10.Can be used with kinds of galvanized or pvc wire

The packaging

RFQ:

Q: Are you trading company or manufacturer ?

A: We are factory. We are warmly welcome clients from worldwide to visit our factory and cooperate with us

Q: Do you do OEM?

A:Yes

Q:Â I know nothing about the import, can you help me?

A: This will not be a problem. If you do not know how to import,  our cooperated freight forwarder will help you to import. You only have to pay a small money to them and they will take careof everything. It is very easy and simple.Q: What should i do if we feel hard to use the machine?

A: If you need ,at any time, we can send our engineers to your factory for training, debugging machine and maintenance.Operating Instruction&Maintenance Manual attached with the machine.we will send you the solution by email or phone within 24 hours,When we receive your service repuest.

We can send you video for learning

Q:If the parts was broken, how about the solution?

A: 1)Non-artificial damage parts, within warranty period, can be provided free of charge    2)Custom-made parts with detailed drawing can be provided

Â

Q:How long is your delivery time?

A: Generally it is 10-15 days if the goods are in stock. or it is 25-30days if the goods are not in stock, it is according to quantity.Â

Q:.How about your machine's working speed and output?

A:Please contact our professional salesman, you can get all the details.

Certification:

Our Service:

1.professional technology team can offer proposal for customers all kinds request

Â

2.Guarantee time: one year since machine was at buyer's factory but within 18 months against B/L date.

3..Within guarantee time, if any components are broken under normal condition, we can change for free.

4.We can send our best technician to buyer's factory for installation, debugging and training.

5.Complete installation instructions, circuit diagram, manual operations and machine layout.

6..24 hours technical support by e-mail.

Contact us         Â

Â

Â

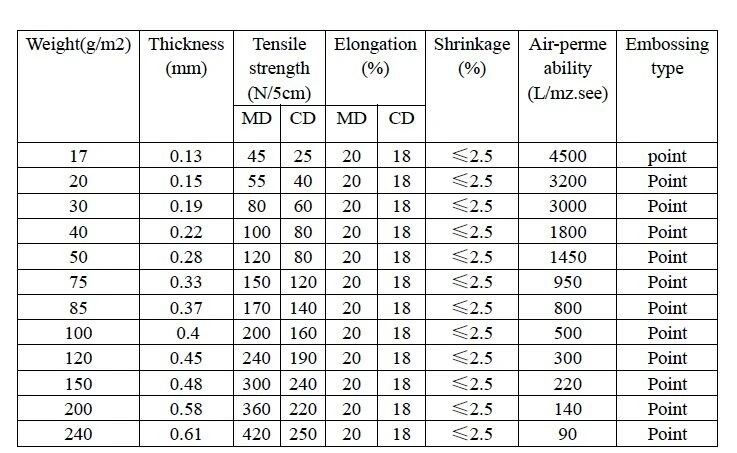

Non Woven Fabric

FY-hengfa nonwoven Fabric series: PET Polyester Spunbond Non woven, Meltblown Nonwoven, Activated Carbon Nonwoven Fabric, Nonwoven Filter Bag,Nonwoven Fabric For Auto Filter.

Such as:

100% PET/PP spunbond nonwoven fabric.

It is similar to filament yarn production. From the chips storage, the polymer is vacuum-fed to a dosing station on top of the extruder. Inside the extruder, it becomes melted and homogenized. Passing a filter system and a spin pump, the melt is fed into the spin beam or spinnerets, which form a curtain of filaments. The filaments are cooled by means of a stream of air in a blowing area, drawn by aerodynamic forces and then transported to the downstream discharge channel. For nonwovens, instead of a further stretching process for filament yarns, the filaments are swirled around and then deposited on the wire mesh belt as a random nonwoven. This web is transferred to a bonding calender that uses heat and pressure to set such physical properties as tensile strength and elongation of the final product. After cooling, the material can be wound.

Product :Spun-bonded Nonwoven

Material :100% polyester

Width :0.15-3.20m.

Specification:1000M-4500M/roll or customized

Weight :10gsm-260gsm

Use :

1. Medical : face mask ,surgical cloth ,bedsheet ,disposable cap , shoose cover .

2. Packing : shopping bag , tablecloth ,wallpaper ,compund packing material .

3. home textile : pillow case ,mattress cover ,linling .

4. Industry : protect the crop from insect .cold weather .filtration materials

Non Woven Fabric

Non Woven Fabric,Pet Non Woven Fabric,Activated Carbon Nonwoven Fabric

Hebei Fangyu Trade Co., Ltd. , http://www.filtersmaterial.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)